Pass Design Grade and Ingredient of Raw Material 2. 3 Jul 2017 Roller Guide for rolling mill are a series of rollers that determine the angle and to increased fuel efficiency and freedom of design increased interior spaceguides assembly and components and we can also design and manufacture according to the rolling mill pass and process to meet the customers demand for guides in the mill stands according to the design.

Rolling Mill Guide Equipments Ispatguru

The rolls are supported in bearing housed in sturdy upright frames called stands which are grouted to the rolling mill floor.

. Design guide plates according to the request of customers. Most jewelers prefer a combination rolling mill because they work with different materials Flat rollers are used for reducing the thickness of sheet metal and imprinting patterns into the metal. After reading this article you will learn about the design of rolling mills.

The mill design innovation focuses on performance improvement of mechanical electrical hydraulic electronic control a nd programming components. A rolling mill guide for use in rod mills merchant mills and the like comprising a guide box two opposed blocks mounted in the guide box on opposite sides of the mill pass line and having longitudinally extending channels in their adjacent faces separate metal plates bridging the respective channels and shaped to flt closely against the sides of the stock traveling through. Cantilever compact mill stands are.

Tendem or Continuous mills 1. Typically speaking as material thickness increases youll need a larger roll shaft diameter for the mill. Two High Rolling Mills It contains two heavy rolls fixed one over the other.

The housing less stands are normally arranged in horizontal-vertical no twist arrangement which allows no twist rolling which permits larger reduction and smoother rolling as it eliminates twisting oval into round passes as in the conventional oval to round sequence which results in less guide wear and simpler guide design. We Have Almost Everything On eBay. Mill guides also could increase the strength of surface of billet.

Wire rollers are used for rolling and reducing the diameter of a wire. In principle the billet will be rolled in the same way as in conventional rolling up to the intermediate rolling mill. Rolling mill guides - Morgårdshammar Guide Equipment Since introducing a revolutionary roller guide product in 1945 we have been leading the international steel industry and introducing a number of patented products for rolling mill systems.

Fast Easy Shipping Nationwide. Ad Tools And Equipment For Jewelers. These original concepts have been continuously developing to meet the market.

Ad Developed to CrushGrind Various Materials with an Optimum Result. Looking For Roller Mill Design. Rolling Mill Pass Design Selection.

Combination rolling mills come with a roller that has a flat and groovy surface. Buy Now Pay Later Monthly Payments Available. Rolling mills having single-stand type are.

Layout and design the Roll Forming Tooling around the flower. Calculate the Estimated Strip Width. Rolling mill is used to reduce successively the thickness of the metal strip as per the requirement.

Although more convenient they sacrifice. Article shared by. For each new tooling requirement the designer should use the following steps.

Roll SizeMax Min Position of Groove 4. Whether it is appropriate to select have a decisive impact to the productivity and output of rolling mills quality consumption index and production process operation so the selection of rolling mill pass. Mill guides could clear oxide scale of billet and make the surface of billet more smooth.

A rolling mill includes one or more roller stands a main drive motor reducing gear stand pinion flywheel and coupling gear between the units. The selection of the rolling mill pass system is an important part of the rolling mill pass design. HeightMax Min Pitch Width Fixing Method 3.

As an example Dahlstrom can form material thicknesses ranging from 0012 to 0200 using mills with roll shaft diameters that range from 1500 to 2563. Cial roll pass design with designated guide Guiding is our business equipment to shape and longitudinally separate the incoming billet into two or more individual strands which will then be further rolled into finish-ed sizes. It is basically consists of housings in which.

The roll stand is the main part of the mill where the rolling process is actually done. A guide for directing a hot rolled product along a path in a rolling mill comprising at least one annular roller arranged to contact the product The roller is rotatably supported on a shaft by bearings defining an axial gap therebetween Fluid is delivered under pressure into the gap and internal vanes respond to the thus delivered fluid by rotatably driving the rollers. For our optimum design we need to know your general rolling mill schedule comprehensive plan and detailed specifications as below.

Produce a Bend Progression or Flower. Mill guides are to help billet safely pass through rolling mill. Ad Fast and Free Shipping On Many Items You Love On eBay.

Rolling Mill Guide About Us YUYI Co Ltd as a professional one-stop supplier is engaged in research design production delivery sales technical services of Copper Mould Tube rolling mill equipment its spare parts stainless steel products refractories for steel mill rolling mill ferro alloy industry foundrymineral processing industry globally. Hot rolling mills are used for mass thickness reduction at high temperatures whereas the cold rolling mills are used as secondary rolling operations to attain more precise dimensional and mechanical properties. Develop a cross-sectional drawing with part material and mill specificationstolerances.

Rolling Mill Guides Morgardshammar

A Simple Guide To Rolling Mill Hill Nashville Guru Mill Hill Rolling Mill The Neighbourhood

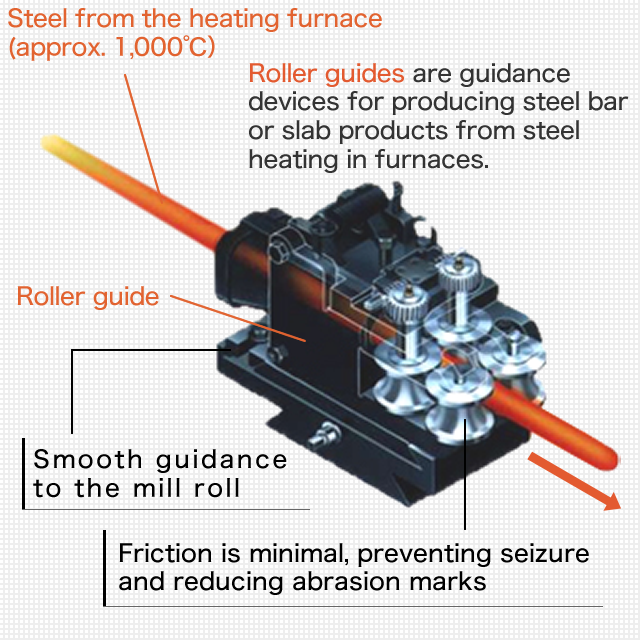

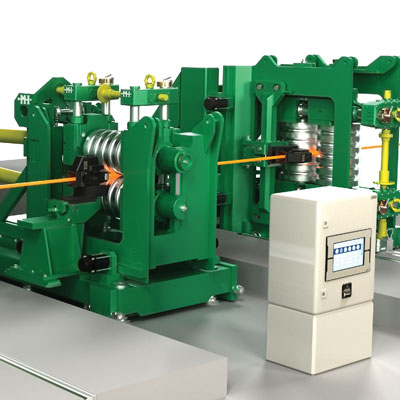

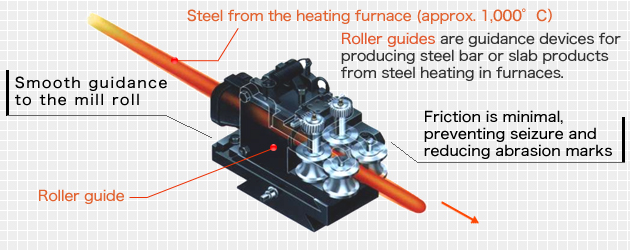

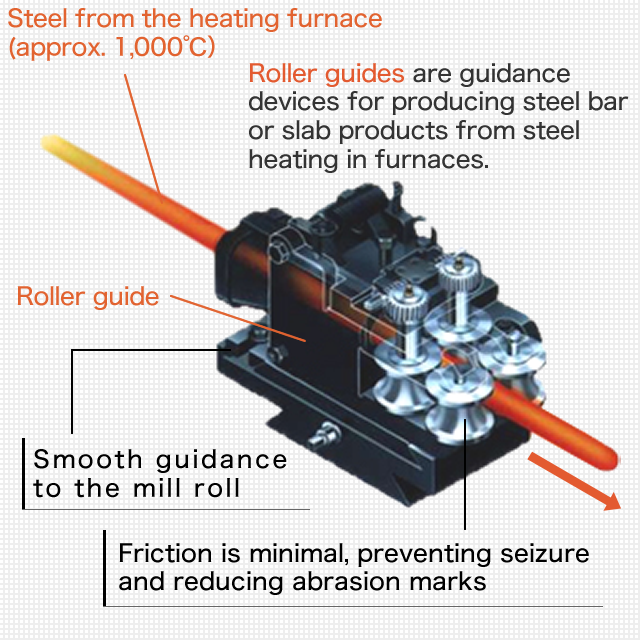

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Sheet Rolling Mills Major Six Types Of Rolling Mills

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Rolling Mill And Its Technological Equipments Ispatguru

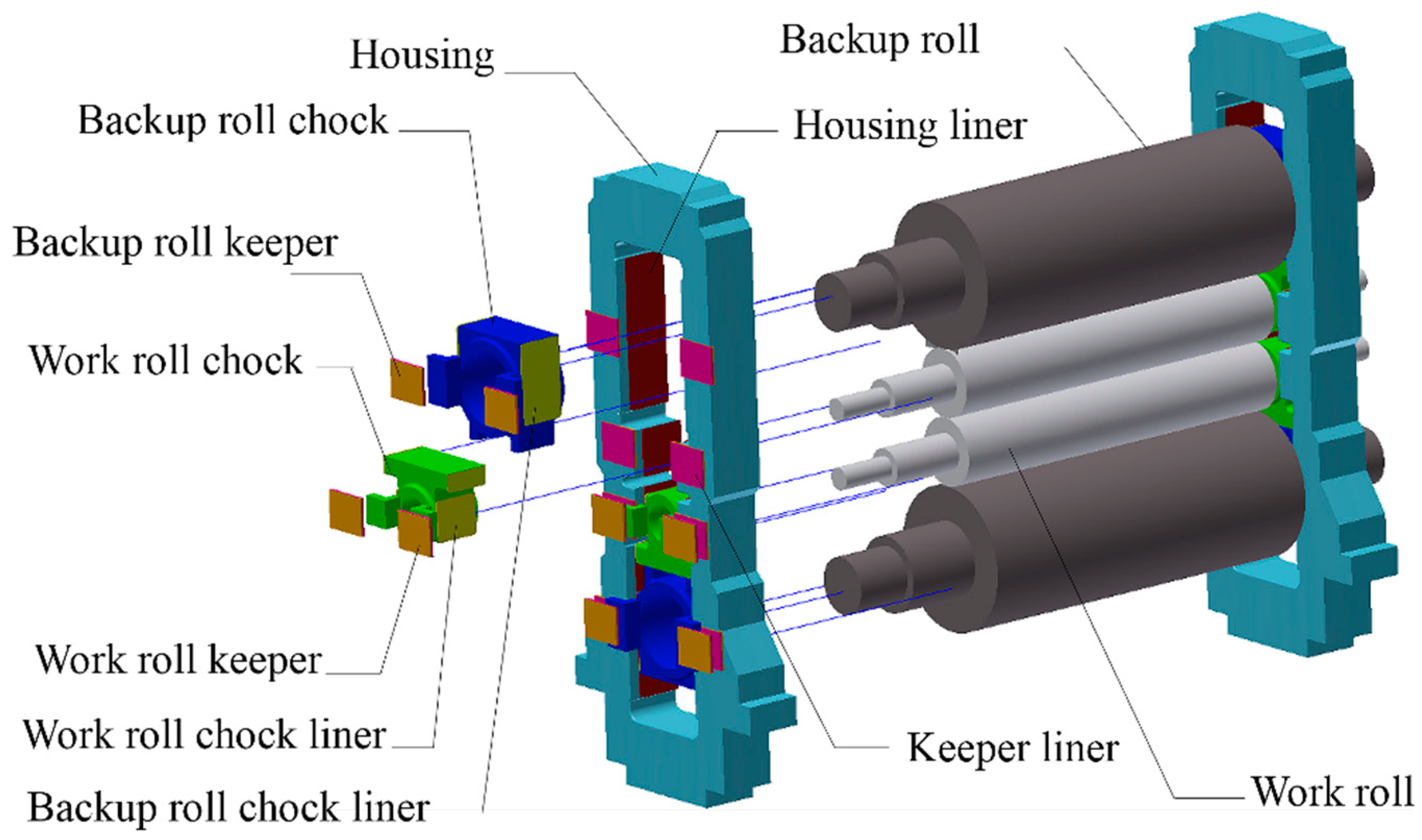

Metals Free Full Text Effect Of Clearances In Mill Stands On Strip End Motion During Finishing Rolling Html

0 komentar

Posting Komentar